Trusted Where Permanent Identification is Critical.

WHAT IS METALPHOTO?

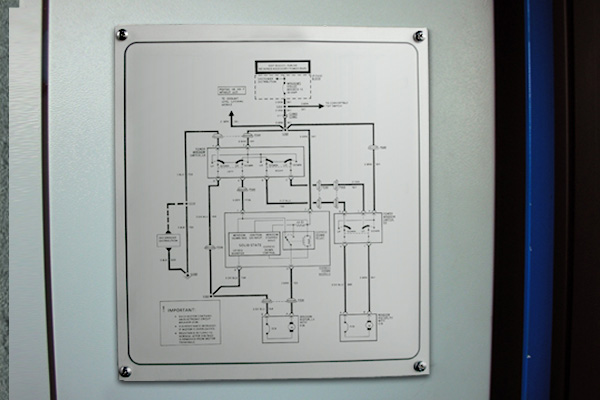

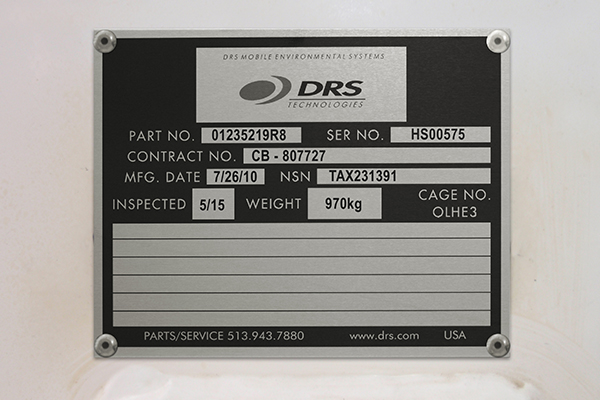

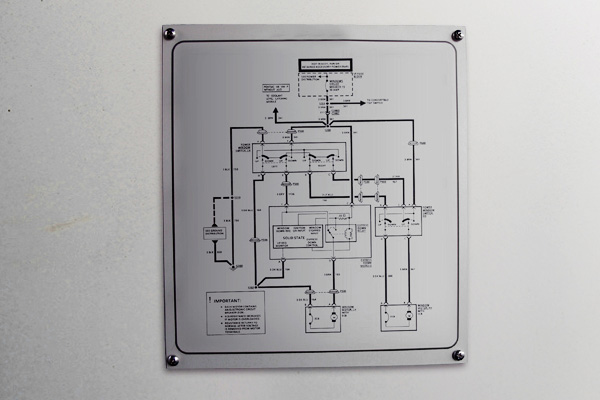

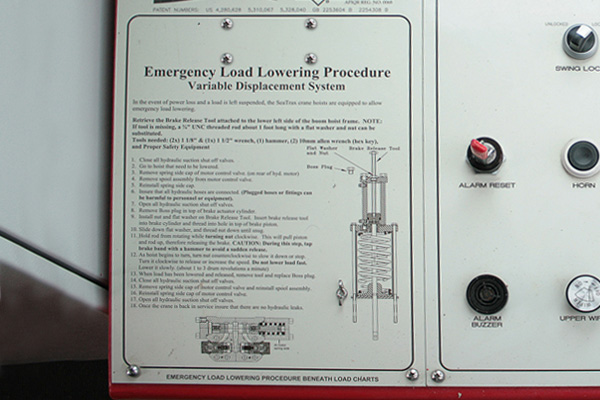

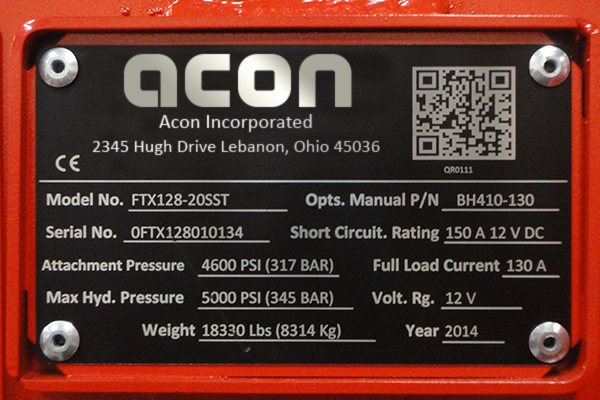

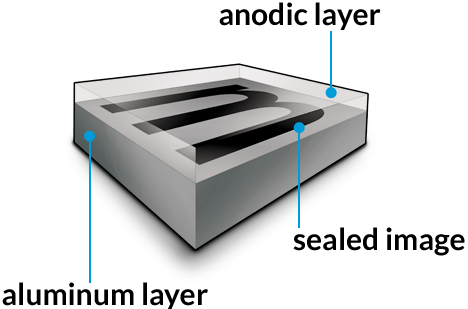

Metalphoto® is photosensitive, anodized aluminum used to make extremely durable, ultra high-resolution nameplates, labels, and control panels with variable data such as barcodes, QR codes or serialized information at scale.

Metalphoto’s durability comes from its archival image – which is sealed inside of the anodized aluminum, providing unmatched resistance to long-term sunlight, saltwater, high-temperature and/or harsh chemical resistance. A US Navy study of 73 materials found Metalphoto to earn the highest possible score on more tests than any other material evaluated.

Its unique, photographic imaging process economically creates a ultra high-resolution graphic and variable information for product identification and asset tracking application such as barcodes/QR codes, anti-conterfeit security and serialized nameplates at a production scale unmatched by other imaging technologies.

Since its development in 1950, Metalphoto has been specified by leading OEMs, military and government organizations for nameplate, label and control panel applications where permanence, resolution, variable data or a combination of those characteristics are required.

Why Use Metalphoto?

Metalphoto’s archival, silver-halide based image is sealed inside of anodized aluminum, making it readable after prolonged exposure to a variety of harsh operating conditions including weather/sunlight, heat, abrasion, chemicals and salt-spray.

The benefit is fewer label, nameplate, sign or control panel replacements due to illegibility – that means guaranteed regulatory compliance, asset identification and brand representation.

Metalphoto’s ability to create hundreds, thousands, even millions of unique labels or nameplates is a function of its unique imaging process.

The benefit of this process is that Metalphoto labels and nameplates can contain “item-unique” serialized data, one of a kind instructions and/or barcodes of any symbology.

Durable barcodes connect assets to cloud-based computer systems, reduce data entry errors and speed the process of identifying assets properly.

- Your label, nameplate or panel will always look crisp and clear – conveying a sense of quality and reliability that will distinguish your brand.

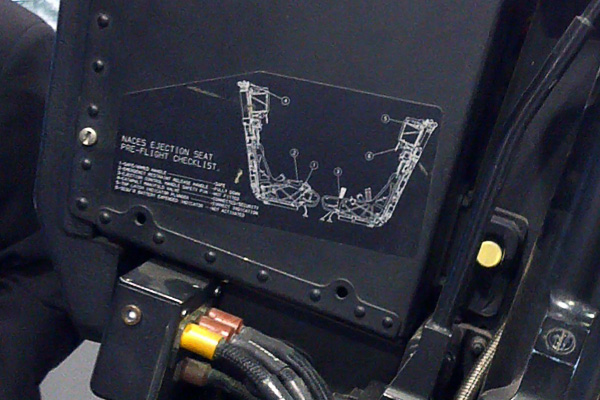

- High-resolution images make it possible to mark small items or surfaces such as firearms or others where a large label is not feasible.

- Optional security printing features such as micro-text and watermarks that verify the authenticity of your product and protect it against fraud and counterfeiting.

Since its introduction in 1950, Metalphoto has proven itself again and again to major OEMs and government organizations. As a result, Metalphoto is specified by most major government, industrial and military organizations including Boeing, Airbus, Caterpillar, Great Dane, Honeywell, BF Goodrich, NASA, and the United States Navy, Army, Air Force and Marines.

When To Use Metalphoto?

Because Metalphoto is resistant to many conditions commonly found in outdoor environments that would erode most identification products printed on other materials, Metalphoto is the perfect material for any nameplates, signs, labels or control panels that need to stand up to harsh outdoor environments, or any project where permanent identification that will remain legible for the life of the product is crucial. See Metalphoto’s durability characteristics below:

Weather/UV Resistance

TESTING

TESTING

Metalphoto was immersed in a full battery of chemicals at different temperatures for different lengths of time, all with little to no effect.

View the Full List of Chemicals and Results

*Horizons ISG does not warrant the performance of its materials in any environment.

When your application calls for a material that will remain legible through the harshest of environments, Metalphoto is your go-to material. These industries all trust Metalphoto for their critical identification applications:

Metalphoto Provides Durable Identification for Defense Applications

Metalphoto’s durability comes from its image – which is sealed inside of the anodized aluminum, providing resistance to corrosion, sunlight degradation, abrasion, high temperatures and chemical exposure. Its unique, photographic imaging process supports ultra-high resolution images and variable information – including machine-readable barcodes, anti-counterfeit security features and serialized data.

APPLICATIONS:

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- MIL-STD-130N

- MIL-DTL-15024G

- MIL-P-19834B

- A-A-50271 Class-2 Composition C

- Federal Specification GGP-455B(3)

To learn more, please download the Metalphoto Defense data sheet or the Metalphoto Defense case study.

Durable Identification for Aircraft and Aerospace Applications

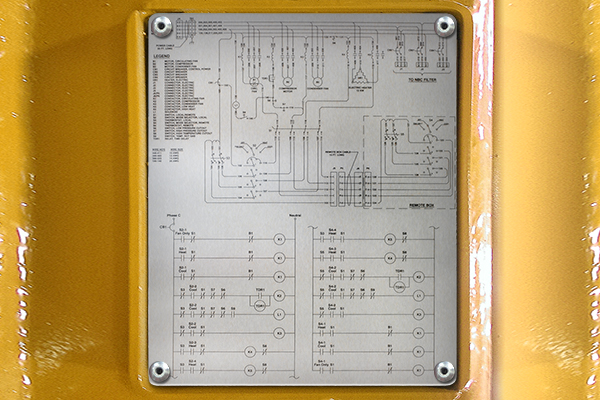

For over 60 years, engineers have trusted Metalphoto® photosensitive anodized aluminium for extremely durable equipment and process identification items installed in demanding operating environments. Specified by Boeing, Airbus, Lockheed Martin, NASA and the United States Department of Defense, Metalphoto is used for applications such as nameplates, barcode labels, maintenance schematics, operator control panels, safety protocols and many others.

APPLICATIONS:

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- Boeing Commercial Aircraft Company, Boeing Process Specification BAC5875, Fabrication of Aluminum Markers, Instrument Panels, Drawer Front Panels and Fabrication of Metal and Plastic Appliques

- Lockheed Martin, LMA-PN010, Fabrication of UID Nameplates for Aircraft Items

- BF Goodrich Aerospace, Data Systems Division, Specification SMT0022

- NASA, Johnson Space Center Texas, Space Station Inventory Label Specification – SSP 50007

- Honeywell, Inc., Satellite Systems Operations, Metalphoto approved for use on Space Station, Memorandum A3-J024-M-9501786, Laboratory Case 161311

To learn more, please download the the Metalphoto Aerospace data sheet or the Metalphoto Aerospace case study.

The Intelligent Metalphoto VIN Tag. A 20-Year Tag for a 20-Year Trailer.

The Intelligent Metalphoto® VIN Tag replaces traditional etched plates because of greater durability and optional machine-readable barcodes. Those features create the following benefits for trailer manufacturers and their customers:BENEFITS TO THE TRAILER MANUFACTURER

- Drive aftermarket revenue – digitally link to sources for OEM aftermarket parts and service.

- Enhance your selling proposition – differentiate your trailer from competitors and offers your customers a series of cost-saving benefits (see below).

- Enhance your brand image – feature a crisp, high-resolution brand logo image that lasts the life of your trailer & demonstrates the quality of your brand.

BENEFITS TO THE FLEET OWNER

- Asset Tracking – end manual data entry with an asset-specific barcode, reducing labor and errors associated with trailer intake at transfer stations and maintenance facilities.

- Asset Maintenance – give the operator and mechanic a service history for each trailer, helping to locate OEM-approved replacement parts and reduce downtime through targeted preventative maintenance.

- Little to No Replacement Costs – its image, which is sealed inside of the anodized aluminum, provides resistance to road-salt corrosion, abrasion and other conditions that can obscure traditional etched steel plates.

- Proven Track Record – used by several leading trailer manufacturers already, the Intelligent Metalphoto VIN Tag is already being deployed by leaders in the industry:

Here’s How It Works:

DURABILITY:

The Intelligent Metalphoto VIN Tag’s durability comes from Metalphoto’s photographic image which is sealed inside of the anodized aluminum, providing resistance to:

- Sunlight degradation (20+ years)

- Road-salt corrosion (30 days in chamber)

- Abrasion (7,000 cycles on tabor abrader)

- High temperatures (1,000°F)

- Chemical exposure (diesel fuel, hydraulic fluid and several others)

RESOLUTION:

The Intelligent Metalphoto VIN Tag supports variable data and barcodes because it is a photographic technology. That means:

- Variable data can be embedded in the plate or punched/scribed your location(s)

- Barcodes reduce data entry errors and time – helping your customer track and maintain your product

- Optional two-dimensional QR code can link mechanics to a maintenance history and parts list of OEM-approved aftermarket parts

- Optional anti-counterfeit features such as watermark and micro-print verify authenticity of your product

In addition to VIN Tags, manufactures use Metalphoto for these permeant identification items:

- CSC Safety Approval Plates

- ISO 6346/BIC intermodal shipping container nameplates

- And other durable nameplates, maintenance schematics and labels

To learn more, please download this case study.

Durable Identification for Shipbuilding & Marine Applications

APPLICATIONS:

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- Norwegian Marine Technology Research Institute (Marintek) corrosion test of anodized aluminum plates – Metalphoto. Report #23.1011.00.0391,

December 8, 1991. - United States Navy Evaluation of Label Plate Material and Attachment Methods Considered of Use on LPD-17. CARDIVNSWC-TR-62-00-05, June 2005.

- United States Navy NAVSEA Corona Division IUID Center Environmental Survivability Testing Report. August 2011.

- Norwegian Marine Technology Research Institute (Marintek) corrosion test of anodized aluminum plates – Metalphoto. Report #23.1011.00.0391,

To learn more, please download the Metalphoto Marine data sheet or the Metalphoto Marine case study.

Metalphoto Provides Durable Identification for Defense Applications

For over 30 years, oilfield engineers have trusted Metalphoto® photosensitive anodized aluminium for extremely durable equipment and process identification items installed in demanding on-shore and off-shore operating environments as well as renewable energy systems. Specified by National Oilwell Varco, Seatrax and the United States Navy, Metalphoto material is used for applications such as barcode labels, maintenance schematics, machine control panels, safety protocols and many others.

APPLICATIONS:

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- Norwegian Marine Technology Research Institute (Marintek) corrosion test of anodized aluminum plates – Metalphoto. Report #23.1011.00.0391, December 8, 1991.

- United States Navy Evaluation of Label Plate Material and Attachment Methods Considered of Use on LPD-17. CARDIVNSWC-TR-62-00-05, June 2005.

- United States Navy NAVSEA Corona Division IUID Center Environmental Survivability Testing Report. August 2011.

Durable Identification for Heavy Equipment Applications

APPLICATIONS:

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- Federal Specification GGP-455B(3)

- MIL-DTL-15024G

- MIL-STD-130N

To learn more, please download the Metalphoto Heavy Equipment data sheet.

HOW TO GET METALPHOTO?

More About Metalphoto?

Specifications

| Military/Government Specifications | Organization | Description |

|---|

GG-P-455B Amendment 3

GG-P-455B Amendment 3

|

US Federal Government | Amendment to Correct Anodic Layer Thickness | |

MIL-DTL-15024G

MIL-DTL-15024G

|

US Dept. of Defense | Identification of Equipment; Type G – Foil Type H – Plate | |

MIL-A-8625F Amendment 1

MIL-A-8625F Amendment 1

|

US Dept. of Defense | Anodizing amendment for Photosensitized (identification) nameplates | |

MIL-P-6906B

MIL-P-6906B

|

US Dept. of Defense | General specification for identification plates for aircraft instruments, accessories, major structural assemblies and aircraft equipment. | |

Federal Specification GG-P-455B(3)

Federal Specification GG-P-455B(3)

|

US Federal Government | Plates and Foils, Photographic (Photosensitive, Anodized Aluminum) | |

A-A-50271 Class 2-Composition C

A-A-50271 Class 2-Composition C

|

US Dept. of Defense | Department of Defense Commercial Item Description – Identification Plate | |

SSP 50007

SSP 50007

|

NASA, Johnson Space Center Texas | Space Station Inventory Management System Bar Code Label Requirements and Specification | |

MIL-STD-130

MIL-STD-130

|

US Dept. of Defense | Identification Marking of U.S. Military Property | |

MIL-A-8625F

MIL-A-8625F

|

US Dept. of Defense | Anodic Coatings for Aluminum & Aluminum Alloys Type II Class 1 (unprocessed or clear) Class 2 (processed) | |

SAE AMS-QQ-A-250/1

SAE AMS-QQ-A-250/1

|

Society of Automotive Engineers (SAE) | Federal Specification, Aluminum 1100 Plate and Sheet (superceded by ASTM B209-10) | |

MIL-DTL-19834C

MIL-DTL-19834C

|

US Dept. of Defense | General Specification for Plates; Identification or Instruction, Metal Foil, Adhesive Backed | |

MIL-STD-13231

MIL-STD-13231

|

US Dept. of Defense | Military Standard Practice – Marking of Electronic Items | |

MIL-P-514D

MIL-P-514D

|

US Dept. of Defense | Plate Identification, Instruction and Marking, Blank | |

MIL-PRF-61002

MIL-PRF-61002

|

US Dept. of Defense | Pressure-Sensitive Adhesive Labels for Barcoding | |

NSA-2B

NSA-2B

|

US Dept. of Defense | Aluminum Foil (annealed only) |

| Industry Specifications | Organization | Description |

|---|

| BMS-26J | Boeing Commercial Aircraft Company | Boeing Material Specification | |

| BAC5875 | Boeing Commercial Aircraft Company | Boeing Process Specification - Fabrication of Aluminum for Markers, Instrument Panels, Drawer Front Panels and Fabrication of Metal and Plastic Appliques | |

| Memorandum A3-J024-M-9501786, Laboratory Case 161311 | Honeywell, Inc. Satellite Systems Operations | Metalphoto approved for use on Space Station | |

| LMA-PN010 | Lockheed Martin | Fabrication of UID Nameplates for Aircraft Items | |

| GA105G | Northrup Grumman | Northrup Grumman Standard | |

| SS9048-R08 | Sikorski | Sikorski Processing Specification | |

| LGMS 3001 | BF Goodrich | Goodrich Specification - Aluminum Material for Nameplates and Foil Labels | |

| SMT0022 | BF Goodrich | Goodrich Specification | |

| CMS6800 | UTC Aerospace Systems/Hamilton Sundstrand | Metalphoto Photosensitive Anodized Aluminum is approved for UTC Aerospace specification CMS6800 for durable plate and foil labels. | |

| Independent Specifications | Organization | Description |

|---|

ASTM B209-14

ASTM B209-14

|

ASTM Standard Practices | Standard Specification for Aluminum and Aluminum Alloy Sheet and Plate | |

Technical Paper Series 2000-01-2437

Technical Paper Series 2000-01-2437

|

Society of Automotive Engineers (SAE) | Special requirements for Crew Interface Labels on the International Space Station, Stephen Gray & Fernando Ramos – Boeing | |

Standard UL 969

Standard UL 969

|

Underwriters Laboratories (UL) | Marking and Labeling Systems | |

EC 1907/2006

EC 1907/2006

|

European Chemicals Agency (ECHA) | REACH Certification | |

CARDIVNSWC-TR-62-00-05

CARDIVNSWC-TR-62-00-05

|

Dept. of Navy | Navy Lab Evaluation of label plate materials and attachment methods considered for use on LPD-17 | |

RoHS Certification

RoHS Certification

|

EC Directive on Waste Electrical and Electronic Equipment (WEEE) | RoHS Certification | |

CSA Approval Doc. 1 | Doc. 2

CSA Approval Doc. 1 | Doc. 2

|

Canadian Standard Association (CSA) | Canadian approval for adhesive-backed Metalphoto products | |

AAMI/CDV-1 ST79:2010/A2.06

AAMI/CDV-1 ST79:2010/A2.06

|

Pacific Biolabs | Steam Sterilization Validation | |

UL PGGU2

UL PGGU2

|

Underwriters Laboratories (UL) | Marking and Labeling System Material Component (File # MH17767) | |

IUID Environmental Survivability Testing Report

IUID Environmental Survivability Testing Report

|

US Naval Surface Warfare Center (NSWC), Corona Division | Evaluation of label materials marked with Item Unique Identification (IUID) | |

A-A-50271 (~MIL-P-514D)

A-A-50271 (~MIL-P-514D)

|

Detroit Testing Laboratory | Certification to specification |

Performance Properties

| Characteristic | Result |

|---|

| Abrasion Resistance | No pronounced image loss, degradation or reduced readability after 7,000 cycles on an abrading wheel. |

| Acid Corrosion | No deterioration or image degradation after 24 hours in 3% nitric acid. |

| Heat Resistance | Standard Metalphoto readable up to 500°F, Image Intensified Metalphoto readable up to 800°F. Both tested for a 24-hour oven exposure. Inquire for heat resistance up to 1,000°F with Extra High Temperature (XHT) treatment. |

| Salt Spray Corrosion | No deleterious effect after a 720-hr salt spray (fog) test. 2,6 “Very Good” corrosion resistance after 113 days seawater exposure. |

| Accelerated Light and Weather Resistance | No pronounced deterioration of legibility after 400-hr carbon arc weatherometer exposure. (Estimated 20+ year outdoor life) |

| Accelerated Oxygen Aging | No discoloration or fading after 96-hr/300 psi/ 70°C oxygen bomb aging. |

| Stain Resistance | No black fading when plates are exposed to tincture of iodine. |

| Cleaning Resistance | No deleterious effects when tested with alkaline cleaners (MILC-87937 or equivalent) for aircraft surfaces. |

| Low Temperature Resistance | No deleterious effect or image fade after 1 hour at -50°F. No impairment of legibility upon exposure at -67°F. |

| Organic Solvent Resistance | No softening, staining or noticeable fade after 24-hr exposure to: JP-4 fuel, Gasoline, Mineral Spirits, Methyl Ethyl Ketone, Turpentine, Turbine & Jet Fuel, Kerosene, Xylol, Acetone, Toluol, Heptane, Trichlorethylene, MIL-H-5606 Hydraulic Fluid and MIL-L-7808 Jet Engine Oil. |

| Fungus Resistance | Visual reading of “0” per ASTM-G21. |

| Thermal Shock | No deterioration after 3 cycles between -65°C and 125°C |

| Moisture Resistance | No deterioration after 10 humidity cycles per MIL-STD-202, method 106. |

Note: Users must test products in the environment in which they are expected to function. ISG does not warrant the performance of its products in untested applications.

Resources

| Data Sheets | Description |

|---|

Metalphoto Data Sheet

Metalphoto Data Sheet

|

Details the composition, features, benefits, characteristics and technical specifications of Metalphoto photosensitive anodized aluminum. | |

Metalphoto Attachment Guide

Metalphoto Attachment Guide

|

Guide to selecting the right attachment method for your Metalphoto product. | |

Metalphoto On-site Processing

Metalphoto On-site Processing

|

Metalphoto can be produced at your location where and when needed or purchased from worldwide network of approved suppliers. This data sheet describes the advantages of processing on-site and the different systems available based on volume requirements. | |

Metalphoto Sustainability Sheet

Metalphoto Sustainability Sheet

|

For over 50 years, engineers have trusted Metalphoto photosensitive anodized aluminum because of its exceptional durability. What you may not know is that the Metalphoto Processing System is designed for reduced environmental impact. This Data Sheet goes through the environmental benefits of the Metalphoto. | |

Metalphoto Engineering and Specifications Guide

Metalphoto Engineering and Specifications Guide

|

The Engineering and Specification Guide contains information to help engineers specify and use Metalphoto for a variety of identification purposes. |

| Case Studies / White Papers | Description |

|---|

Metalphoto for Photographic Reproduction

Metalphoto for Photographic Reproduction

|

Two Cleveland companies join forces to recognize renovation of historic building and replace low-quality photographic reproductions with high-resolution Metalphoto photosensitive anodized aluminum. | |

Metalphoto vs. Etched Stainless Steel White Paper

Metalphoto vs. Etched Stainless Steel White Paper

|

Etched and filled stainless steel underperforms Metalphoto photosensitive anodized aluminum in select applications. | |

Metalphoto NADCAP Exemption White Paper

Metalphoto NADCAP Exemption White Paper

|

Metalphoto has been exempted from NADCAP AC7108 by several aerospace Primes and Suppliers. This explains why Metalphoto has been exempted & why it is important for others to exempt Metalphoto from NADCAP. | |

Metalphoto IUID Environmental Survivability Test White Paper

Metalphoto IUID Environmental Survivability Test White Paper

|

This US Navy study shows Metalphoto labels to have outstanding durability and versatility for permanent asset identification & tracking. | |

Metalphoto Medical White Paper

Metalphoto Medical White Paper

|

Metalphoto is proven to withstand multiple sterilization cycles & not fade or harbor bacteria as per ANSI/AAMI ST79 steam sterilization & sterility assurance. | |

Metalphoto for Architectural Signage

Metalphoto for Architectural Signage

|

Award-winning Mariemont School Foundation chose Metalphoto photosensitive anodized aluminum for permanent images to last a lifetime. | |

Metalphoto for Transportation

Metalphoto for Transportation

|

A leading manufacturer of tractor trailers and shipping containers found that nameplates made of Metalphoto have greater durability and legibility than etched stainless steel at a fraction of the price. | |

Metalphoto for Marine & Offshore Oil and Gas Drilling

Metalphoto for Marine & Offshore Oil and Gas Drilling

|

Seatrax, a leading offshore crane manufacturer, chose Metalphoto for extreme durability and fast turnaround on permanent labels and markings. |

| Industry Sheets | Description |

|---|

Metalphoto for Transportation

Metalphoto for Transportation

|

Data sheet detailing Metalphoto's use in the transportation industry. | |

Metalphoto for Heavy Equipment

Metalphoto for Heavy Equipment

|

Data sheet detailing Metalphoto's use in the heavy equipment industry. | |

Metalphoto for Energy

Metalphoto for Energy

|

Data sheet detailing Metalphoto's use in the energy industry. | |

Metalphoto for Shipbuilding & Marine

Metalphoto for Shipbuilding & Marine

|

Data sheet detailing Metalphoto's use in the shipbuilding and marine industry. | |

Metalphoto for Aerospace

Metalphoto for Aerospace

|

Data sheet detailing Metalphoto's use in the aerospace industry. | |

Metalphoto for Defense

Metalphoto for Defense

|

Data sheet detailing Metalphoto's use in the defense industry. |

| Webinars / Presentations | Description |

|---|

Destructive Nameplate Testing: Will It Read?

Destructive Nameplate Testing: Will It Read?

|

Webinar presentation testing the durability of Metalphoto versus several competitors through several destructive tests. | |

Metalphoto Road Show Presentation

Metalphoto Road Show Presentation

|

Overview of Metalphoto applications and options |

| Press Releases / Articles | Description |

|---|

Advertisement: Integrity at the Helm: USS Gerald R. Ford (CVN 78)

Advertisement: Integrity at the Helm: USS Gerald R. Ford (CVN 78)

|

Released by Horizons, Inc. July 16, 2017 | |

Metalphoto Introduces Certified Converter Program

Metalphoto Introduces Certified Converter Program

|

Released by Horizons, Inc. September 29, 2015 | |

Synopsis of U.S. Naval Surface Warfare Center, Corona Division’s IUID Testing Compares Durability of 73 IUID Label Materials

Synopsis of U.S. Naval Surface Warfare Center, Corona Division’s IUID Testing Compares Durability of 73 IUID Label Materials

|

Released by Horizons, Inc. April 1, 2014 | |

Horizons Imaging Systems Group Joined AIM North America to Exercise Their Voice on Capitol Hill

Horizons Imaging Systems Group Joined AIM North America to Exercise Their Voice on Capitol Hill

|

Released by Horizons, Inc. June 25, 2012 | |

Metalphoto Achieves Highest Score on More U.S. Navy Environmental Survivability Tests than Any Other Material Tested

Metalphoto Achieves Highest Score on More U.S. Navy Environmental Survivability Tests than Any Other Material Tested

|

Released by Horizons, Inc. November 11, 2011 | |

Supplier Profile: Innovative and Durable Products -Horizons Incorporated

Supplier Profile: Innovative and Durable Products -Horizons Incorporated

|

Published by Recognition Review February 2011 |